I-ROX sits at the apex of a climate-tech and clean-energy innovation matrix. Together with our partners, we are committed to creating and scaling disruptive new technologies that will revolutionize mining and provide a greener, more sustainable world for future generations.

Changing how energy is produced and consumed is essential to achieving ambitious net-zero targets by 2050 and a more sustainable future for all.

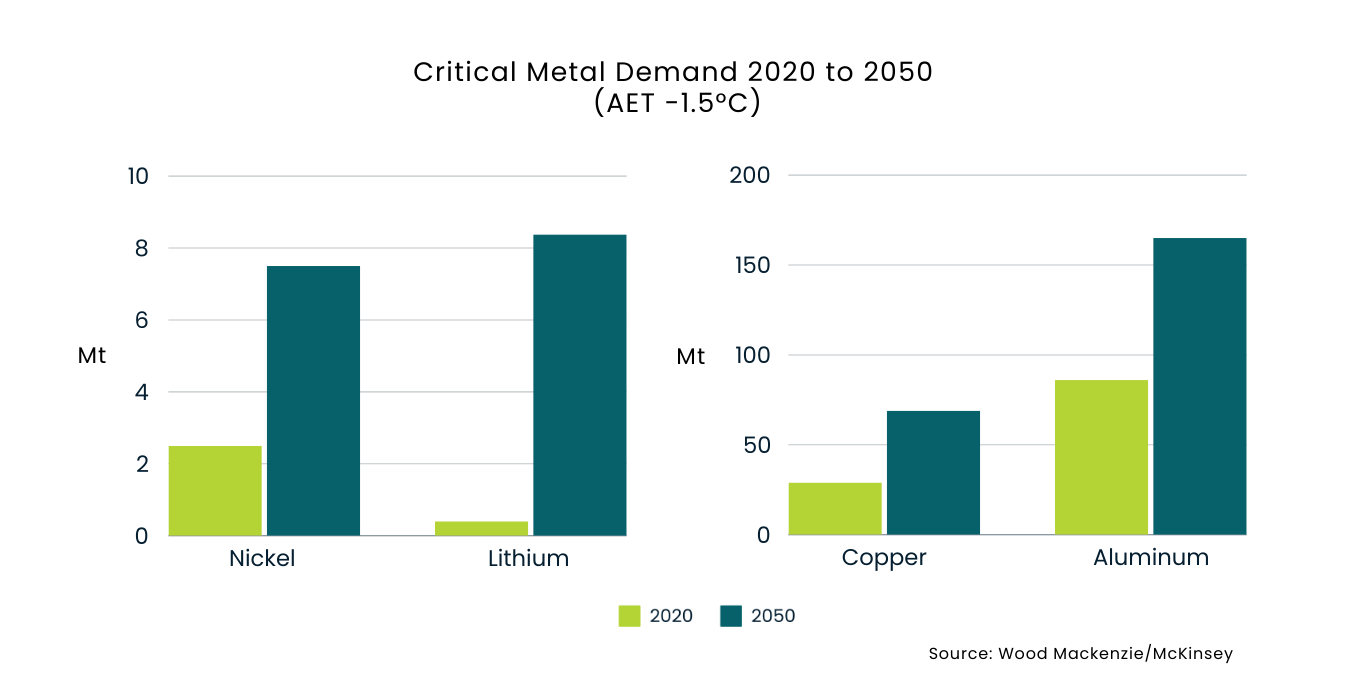

Meeting this challenge requires a significant increase in the production of minerals and metals, but this must be done sustainably. At the same time, large mineral deposits are being discovered less frequently and new mines are taking longer than ever to bring into production. It is therefore increasingly important to maximize the productivity of existing mining operations.

The mining and metals industry contributes around 15% of global emissions. As the demand for minerals critical to the energy transition increases, so does the urgency to address these emissions. The mining industry faces the dual challenge of expanding production to meet this demand while significantly reducing its carbon footprint.

Most major mining companies have set emission reduction targets, many with a long-term ambition to fully decarbonize through energy efficiency, electrification, and renewable-energy use. However, it is clear that incremental changes to existing mineral extraction processes are not sufficient and innovation is a vital tool that will shape the next chapter in mining and enable the energy transition.

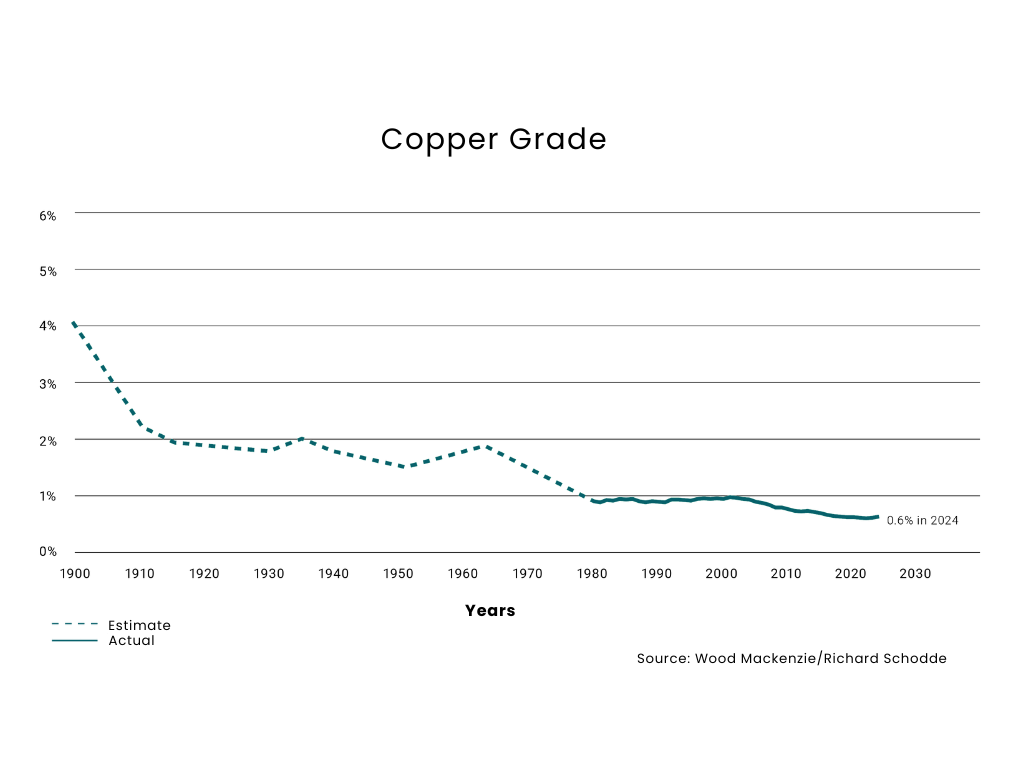

Today, the comminution of mineral ore is performed by mechanical crushing and grinding into progressively smaller sizes. This is incredibly energy-intensive and the problem is exacerbated by the continued decline in global average ore grades. This issue is particularly acute in the copper sector, where grades have fallen from around 4% in 1900, to 1% in 1990 and just 0.6% today. Yet all of the material must be reduced down to the same particle size, meaning that huge volumes of energy are expended to grind material which is over 99% barren.

The result is that up to half a mine’s energy consumption is used to grind rock, resulting in around 2% of the world’s electricity and this equates to over 300Mt CO2e – similar to the emissions of a country like the United Kingdom. I-ROX’s pulsed-power technology solution aims to break rock using a fraction of the energy used by traditional milling equipment, thereby radically reducing emissions and saving billions of dollars across the mining sector.