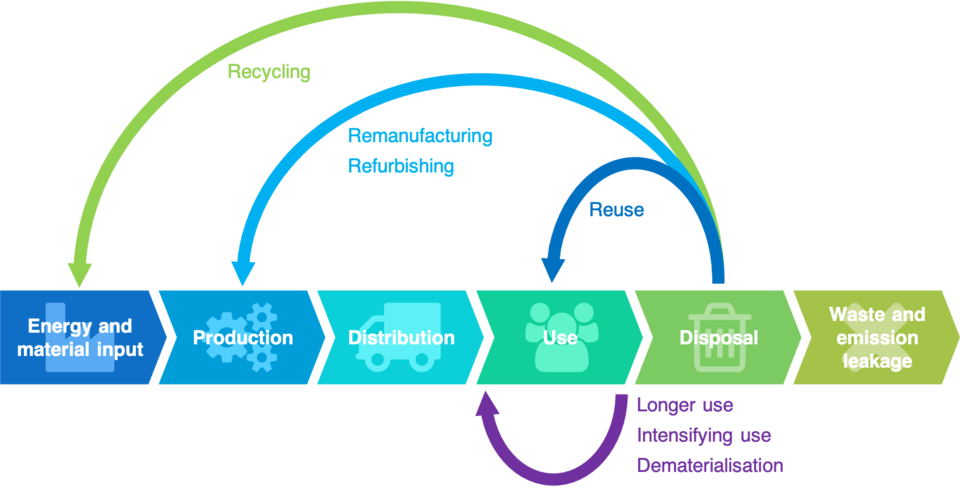

The energy transition is not only about adopting renewable energy sources but also transforming how resources are used, reused, and recycled to ensure long-term sustainability. The circular economy provides a sustainable framework for achieving this by reducing waste, promoting efficient recycling methods, and extending the life cycle of materials critical to energy technologies. Efficient recycling of batteries, solar panels, and other technologies will reduce reliance on virgin mining while conserving resources, and innovations in recycling technologies and strategic approaches to material recovery are essential to advancing this framework. The mining industry has a unique opportunity to complement circular practices by integrating recycled materials into its supply chains.

- The role of recycling and reducing waste in the energy transition

- Innovations enabling the circular economy

- Mining and the value of recycled critical minerals

The role of recycling and reducing waste in the energy transition

Achieving a sustainable energy transition depends on optimizing resource use and minimizing waste. Recycling, reusing, and reducing waste are critical strategies to create a circular economy that aligns with global net-zero goals. Key areas include battery recycling, reuse of materials from decommissioned technologies, and minimizing waste in production processes.

Lithium-ion batteries are central to the renewable energy transition, powering electric vehicles (EVs) and grid storage. Recycling these batteries helps recover critical materials such as lithium, cobalt, and nickel, which are essential for producing new batteries. Leading circular materials technology companies are pioneering recycling systems that recover over 95% of key metals, reducing the need for virgin mining and addressing supply chain vulnerabilities. By 2040, battery recycling could supply up to 10% of global lithium and 35% of cobalt demand, according to BloombergNEF.

Wind turbines, solar panels, and other renewable technologies have finite lifespans, creating a growing need for material recovery at the end of their use. Approximately 90% of a wind turbine’s mass, including steel, aluminum, and copper, can be recycled, while innovations in solar panel recycling can recover up to 95% of silicon and other materials, which can be reintegrated into new panels. However, recycling wind turbine blades and certain solar panels present significant environmental challenges due to their complex material compositions.

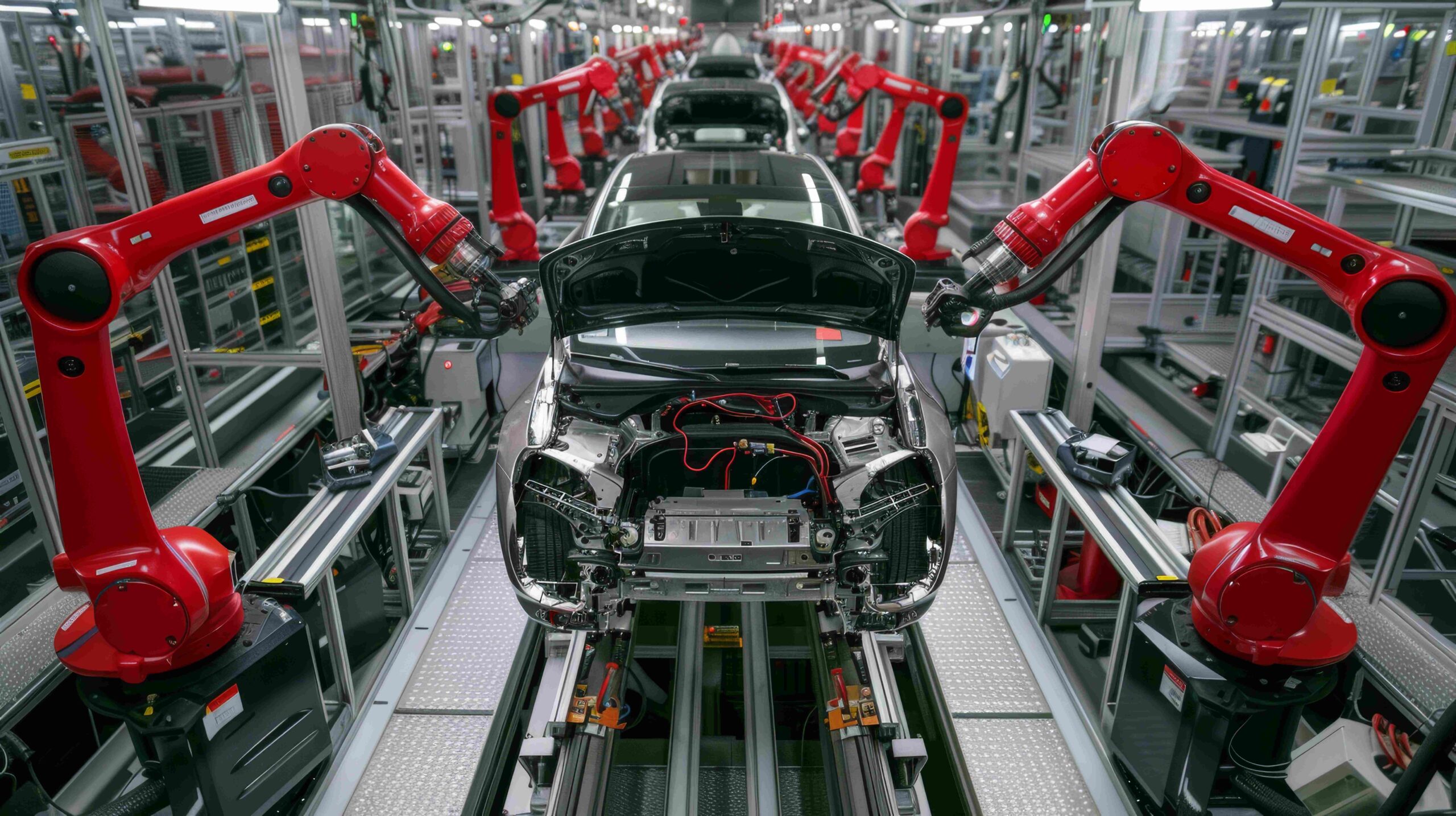

Circular practices extend beyond recycling to include reducing material waste during manufacturing. Advanced production techniques like 3D printing and AI-driven material optimization are helping industries minimize raw material use. For example, Siemens is employing additive manufacturing to produce wind turbine components with near-zero waste, demonstrating how production processes can align with circular economy principles.

Innovations enabling the circular economy

The circular economy relies on innovations that enhance recycling efficiency, enable material reuse, and optimize production. Emerging technologies and forward-thinking strategies are advancing the global transition toward sustainable resource management.

Innovations in recycling technologies are transforming material recovery rates and efficiency. Hydrometallurgical and direct recycling methods for lithium-ion batteries allow materials like lithium and cobalt to be extracted with minimal energy use. Companies like Li-Cycle are commercializing hydrometallurgical processes that recover 95% of critical metals, while American Manganese is developing a patented process to recover cathode materials directly. These advancements reduce reliance on traditional smelting, which is energy-intensive, and significantly improve circularity in the battery supply chain.

Digital technologies are enabling better tracking of materials throughout their lifecycle. Blockchain-based systems allow manufacturers to trace critical minerals from mining to recycling, ensuring transparency and ethical sourcing. AI-driven tools are optimizing recycling operations by analyzing material flow and predicting recycling yields, e.g. Recycleye, a UK-based company, uses AI to improve waste sorting efficiency, reducing contamination, and boosting recycling rates.

Companies are adopting circular business models to improve material recovery and extend product life cycles. Battery-as-a-service (BaaS) models allow EV batteries to be swapped and refurbished, reducing waste and ensuring valuable materials are reintegrated into the supply chain. Similarly, leasing models for renewable energy equipment, such as solar panels and wind turbines, incentivize manufacturers to design products with recyclability in mind.

While ~90% of wind turbines can be recycled, the wind turbine blades are primarily made of composite materials like fiberglass and carbon fiber which are difficult to recycle, especially due to the sheer size of the blades and the amount of fiberglass/carbon fiber in each one, so traditional methods often lead to these blades ending up in landfills. Innovative approaches are emerging however, such as mechanical recycling, where blades are shredded and repurposed into products like decking boards and pallets. Cement co-processing is another method, where shredded blade materials are used as a substitute for raw materials in cement kilns, reducing the need for coal. Additionally, projects like the Re-Wind Network are exploring repurposing blades into pedestrian bridges and other structures, due to their impressive size vs strength ratio.

Solar panels, particularly silicon-based ones, contain valuable materials like silver, copper, and silicon. However, recycling them is challenging due to the encapsulation of these materials within layers of glass and polymer. Current recycling methods include mechanical, thermal, and chemical processes, each with its own drawbacks. The lack of standardized panel designs and insufficient recycling infrastructure further complicate the process. Efforts are underway to improve recycling technologies and establish regulations to manage the growing volume of solar panel waste. Programs like Europe’s PV CYCLE are setting benchmarks for recycling solar modules and promoting reuse in the energy sector.

Addressing these recycling challenges is crucial for the sustainability of renewable energy technologies. Advancements in recycling methods and supportive policies are essential to mitigate environmental impacts and promote a circular economy in the renewable energy sector.

Mining and the value of recycled critical minerals

The mining industry plays a dual role in the energy transition by supplying the raw materials essential for renewable technologies and incorporating recycled materials to reduce pressure on virgin mining operations. Integrating circular practices strengthens supply chains and ensures sustainable resource management.

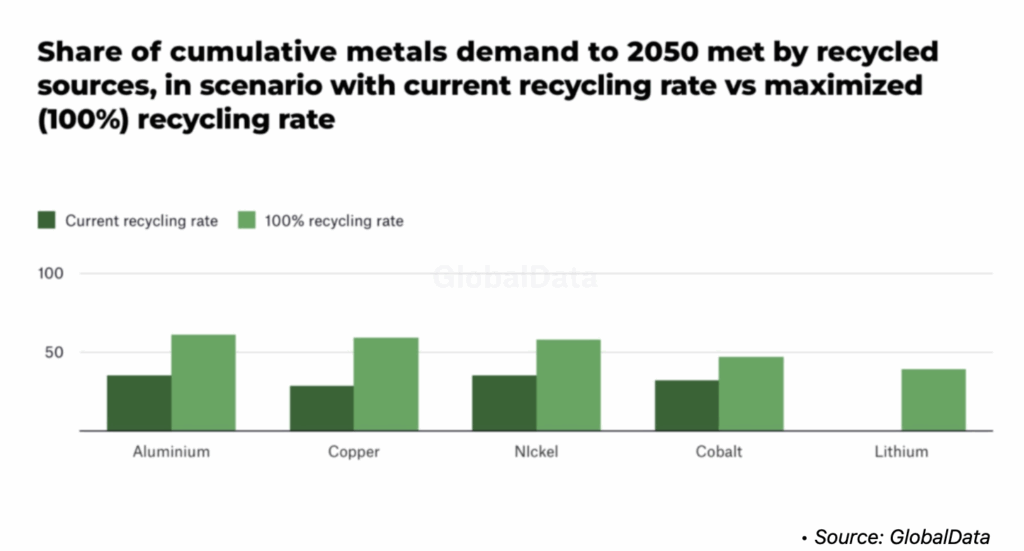

Recycling critical minerals from batteries and electronics reduces the demand for virgin mining, conserving resources and easing pressure on new extraction projects. For example, cobalt recovered from recycled batteries could meet over 25% of EV battery demand by 2035, according to the International Energy Agency. Mining companies are increasingly collaborating with recycling firms to integrate secondary materials into their supply chains, complementing primary resource extraction.

Recycled materials offer a reliable supplement to mined resources, particularly as demand outpaces supply for critical minerals like lithium and nickel. Major mining companies like Glencore are partnering with recycling firms to create hybrid supply chains that blend primary and secondary materials. This approach not only ensures resource availability but also aligns mining operations with circular economy principles, reducing emissions and waste.

Recycling also strengthens supply chains by mitigating geopolitical risks associated with sourcing minerals. For example, more than 70% of global cobalt is mined in the Democratic Republic of Congo, creating vulnerabilities for manufacturers reliant on single-source suppliers. By recovering critical minerals from recycled products, industries can reduce dependency on high-risk regions and stabilize material flows. This diversification is critical to maintaining supply chain resilience as the energy transition accelerates.

The circular economy is an essential component of the energy transition, not just a sustainability initiative. By combining innovation, strategic partnerships, and efficient resource management, industries can reduce costs, ensure material security, and drive long-term resilience. Embracing circular practices will not only accelerate decarbonization but also shape a future where economic growth and sustainability go hand in hand.

- Explore the next article in our Energy Transition series: Financing the Energy Transition – Trends, Innovations, and Sustainable Mining Investments

I-ROX is open to industry input, collaboration and support – both financially and technically. If you are interested in discussing pulsed-power technology or any other element of collaboration, please contact us for more information.